| Home | S-100 Boards | History | New Boards | Software | Boards For Sale |

| Forum | Other Web Sites | News | Index |

|

|

|

|

|

|

|

|

|

|

A31,30,29,28,27,26,25,24,23,

22,21,20,19,18,17,16,15,14,13,12,11,10,9, 8, 7,

6, 5, 4, 3, 2,

1, 0 0 0 0 0 0 0 1 0 0 x x x x x x x x x x x x x x x x x x x x x x x 0 0 0 0 0 0 1 0 1 x x x x x x x x x x x x x x x x x x x x x x x 0 0 0 0 0 0 1 1 0 x x x x x x x x x x x x x x x x x x x x x x x 0 0 0 0 0 0 1 1 1 x x x x x x x x x x x x x x x x x x x x x x x |

|

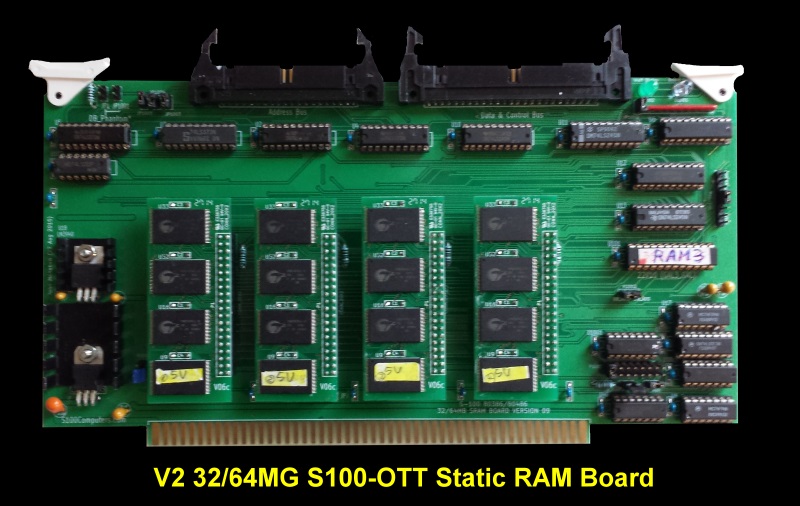

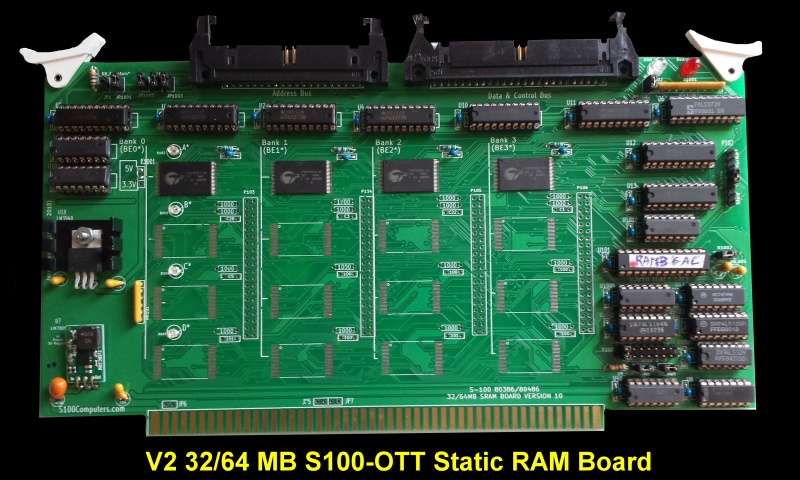

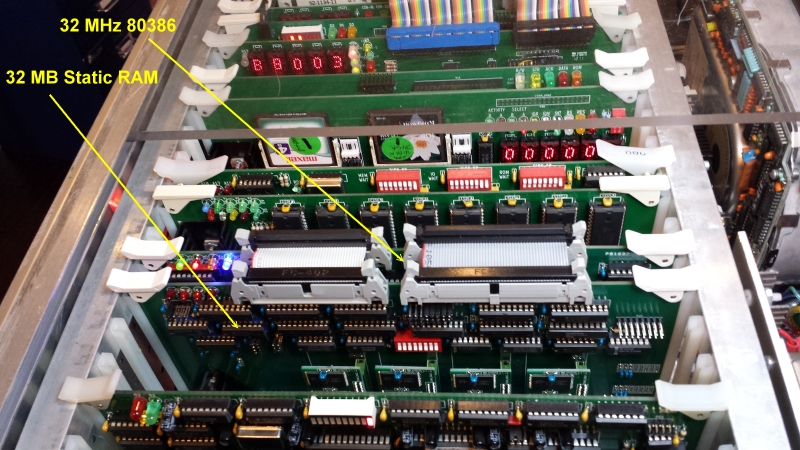

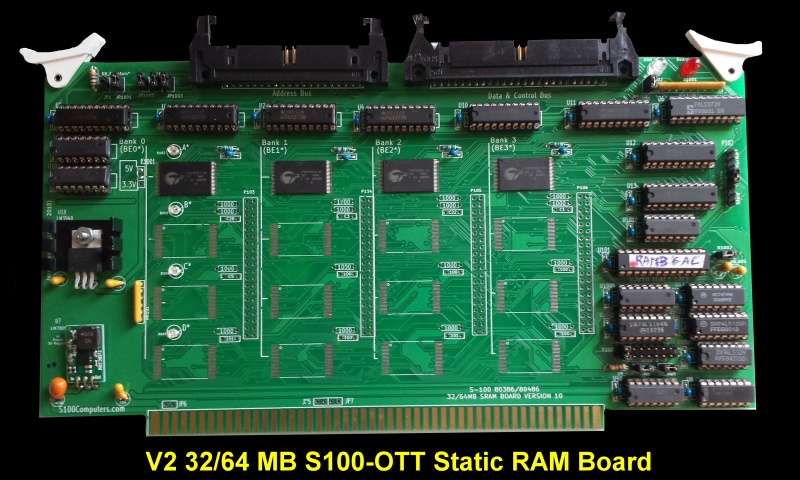

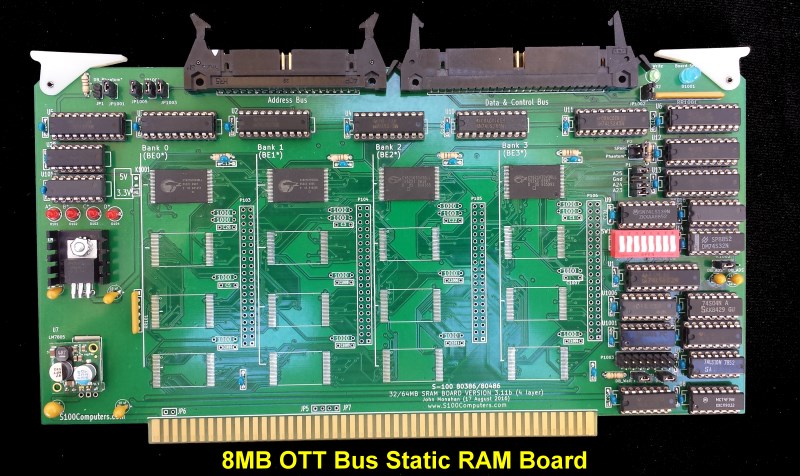

I did not want to change the basic RAM board circuit. It has proven itself to be very reliable with our 80386 CPU board

I wanted to hand lay down broad power traces to all the boards IC’s for more even power distribution.

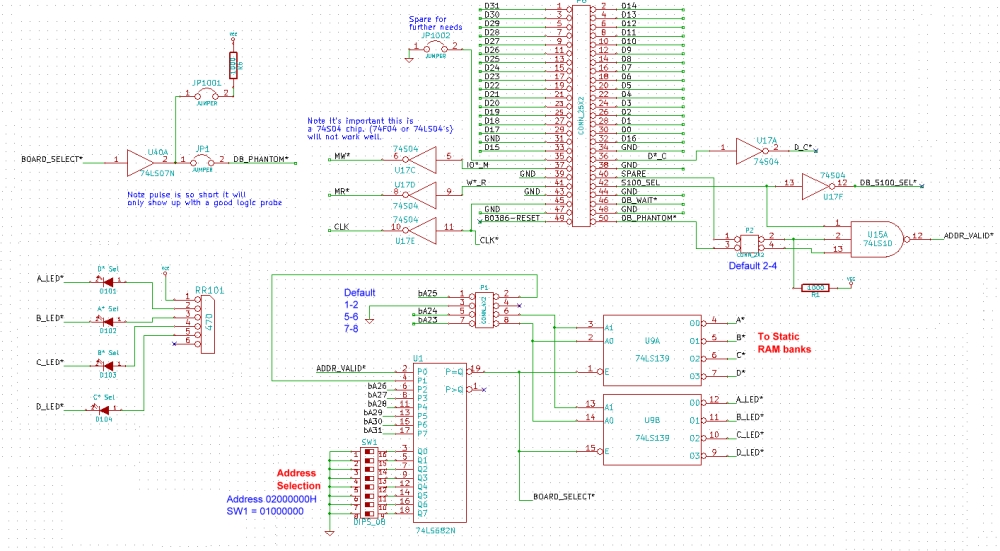

This board utilizes the new RAM read and RAM write signals for memory access (see the V2 80386 board for more info). It can still be run with the earlier 80386 specific M/IO*, D/C* and W/R* which are now decoded in the onboard GAL.

The one 22V10 GAL to replace a number of 74LSxx chips. This simplifies the board and somewhat speeds up the RAM access times. I realize not everybody is familiar with GAL’s. Please see

People should be able to simply switch IC’s from the old board to this new one. One new GAL ICs is the only major change.

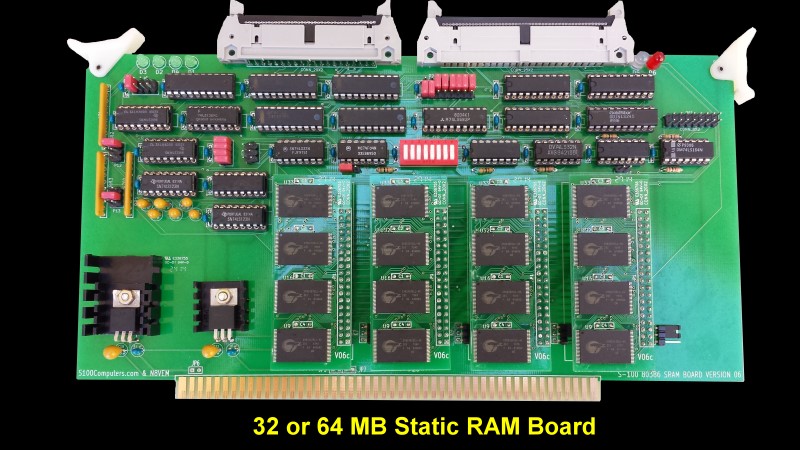

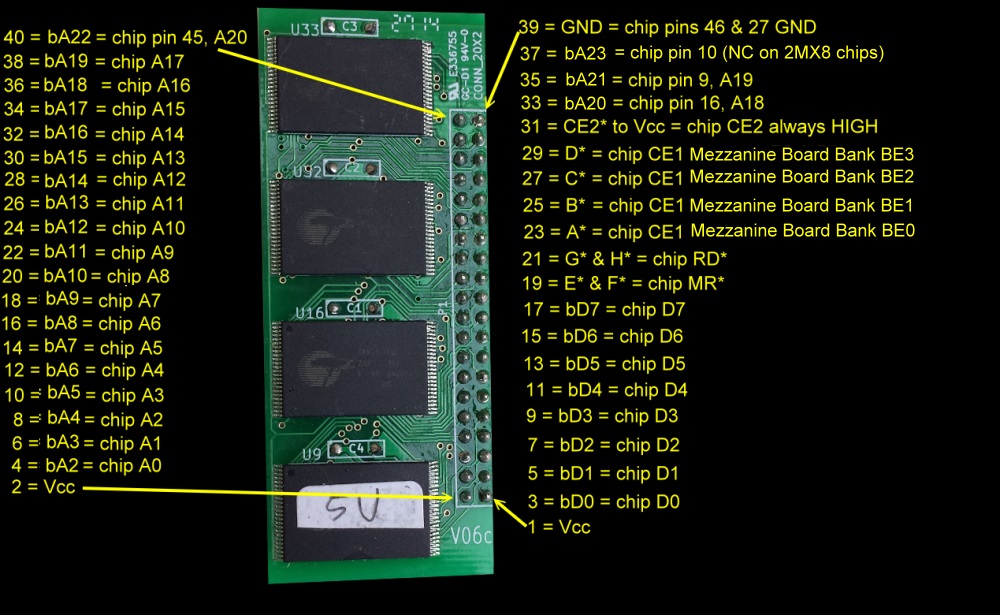

The board can accommodate EITHER four Mezzanine RAM boards described above (V6.0c), for 32MG of static RAM, or 8MB, 16MB, 24MB or 32MB by soldering the

I relabeled much of the Silk Screen to be more relevant. For example placing IC numbers above their pin locations etc.

Extra a long solder pads have been used to allow simpler alignment and soldering of the RAM chips to the board. This makes soldering a lot of chips to the board tolerable.

|

|

|

|

This page was last modified on 11/30/2017